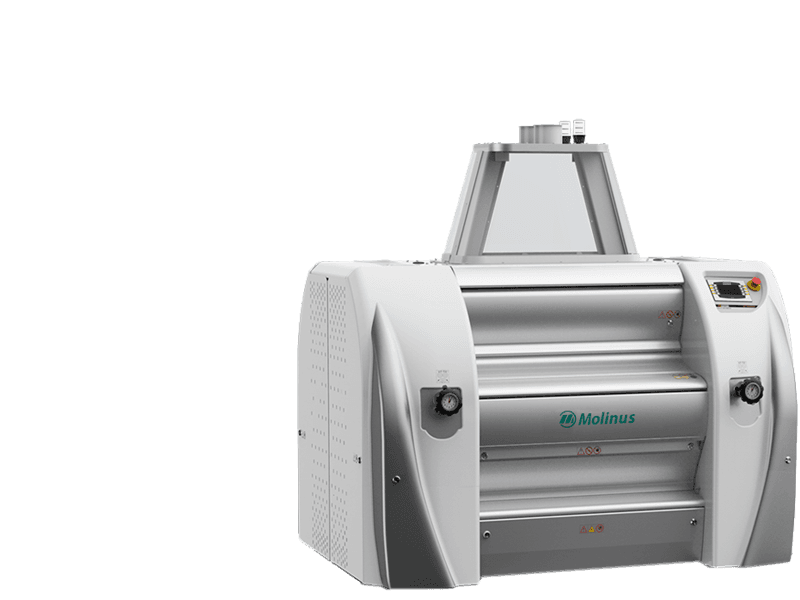

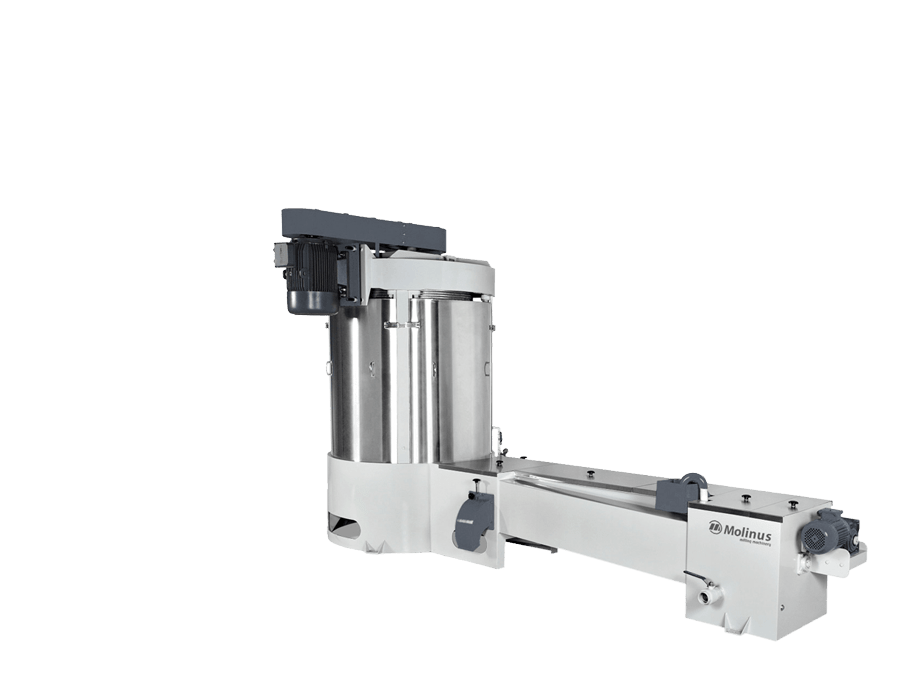

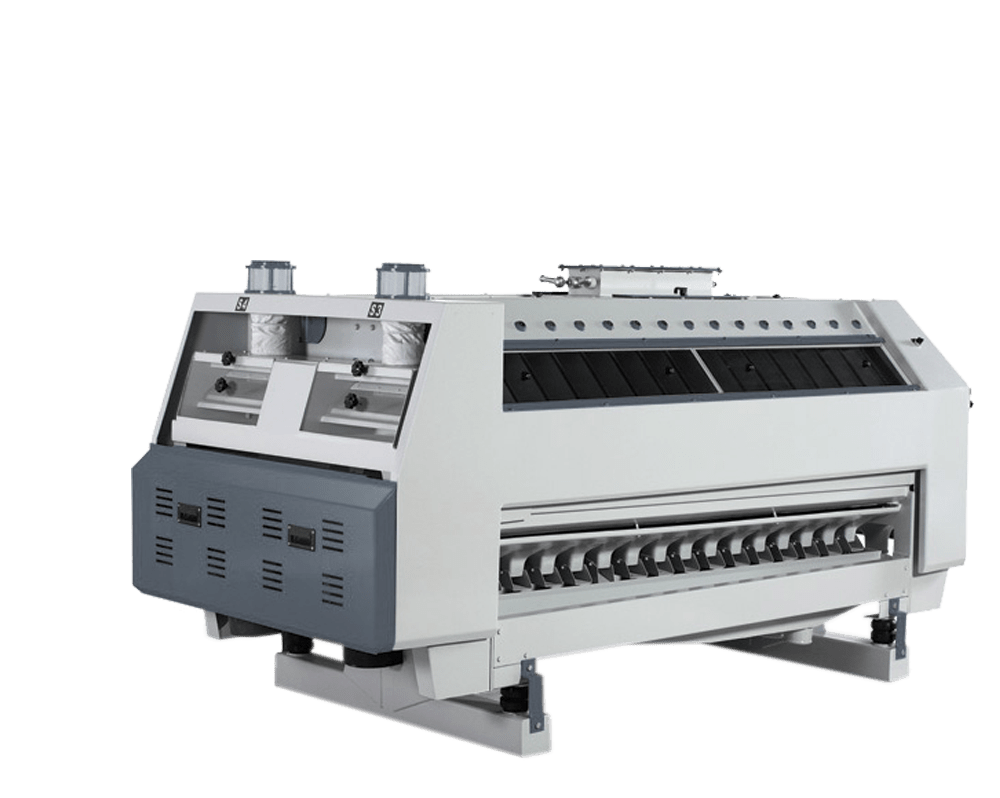

The grain enters the roller mill through product inlet hopper, from which it is conveyed to the feeder rolls and then to the milling rolls.

Capacitive level sensors or loadcells adjust amount of the grain which is placed in the product inlet hopper.

A pneumatic system is used for the automatic engagement/disengagement of the milling rolls and for adjusting milling distance,

using a graduated hand-operated Wheel.

Roller mills have huge power and capacity and they have excellent design. To hold the volume of flowing product at a fix value , the feedig inlet was controlled automatically. So a regular operation and high quality product were obtained.

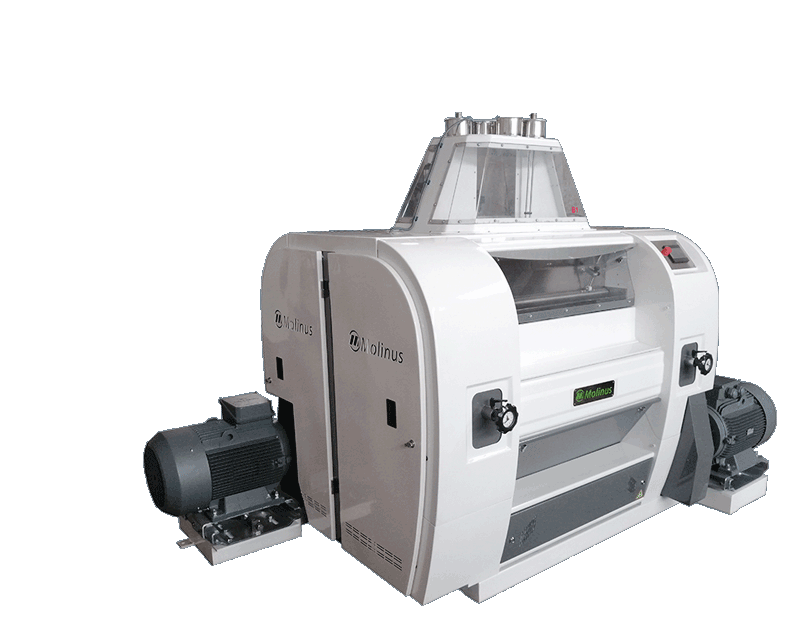

It is specially produced for degirmen, which is especially difficult to place.

Unlike Normal waltzes, the motors are integrated on the Waltzes, making them more convenient and much easier to install..

Thanks to its PLC-based operation, it can be easily integrated into any system.

Roller mills have huge power and capacity and they have excellent design. To hold the volume of flowing product at a fix value , the feedig inlet was controlled automatically. So a regular operation and high quality product were obtained.

It is specially produced for degirmen, which is especially difficult to place.

Unlike Normal waltzes, the motors are integrated on the Waltzes, making them more convenient and much easier to install.

Because of its internal absorption, it does not have any connection with the lower floors.

Thanks to its PLC-based operation, it can be easily integrated into any system.

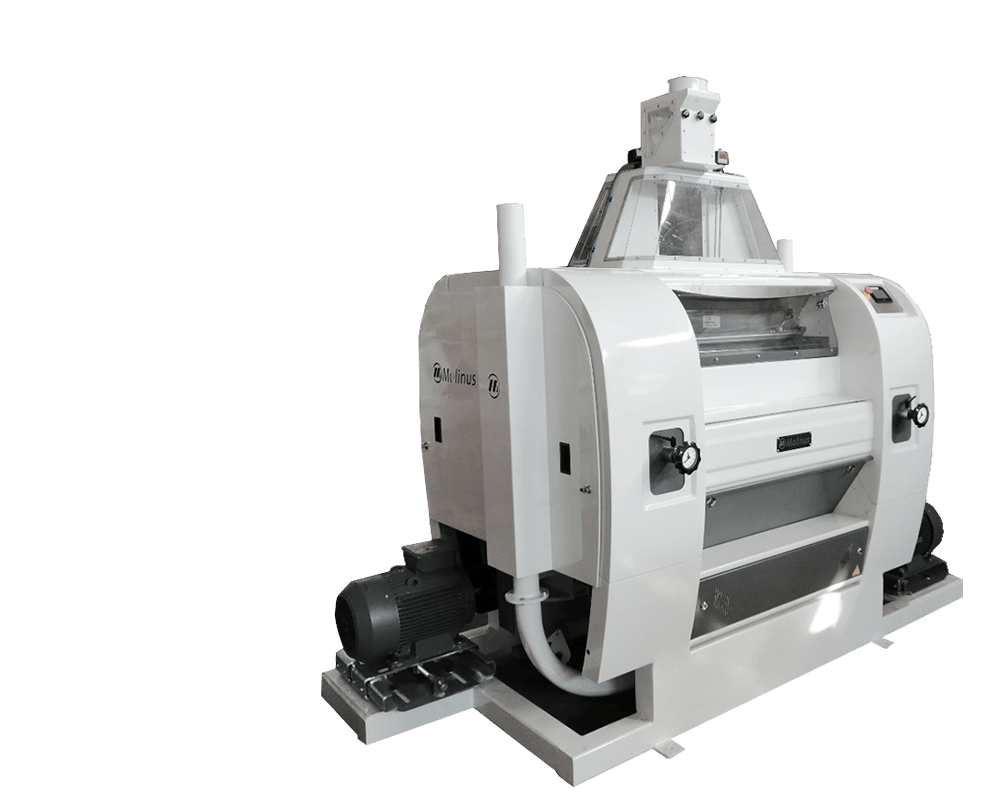

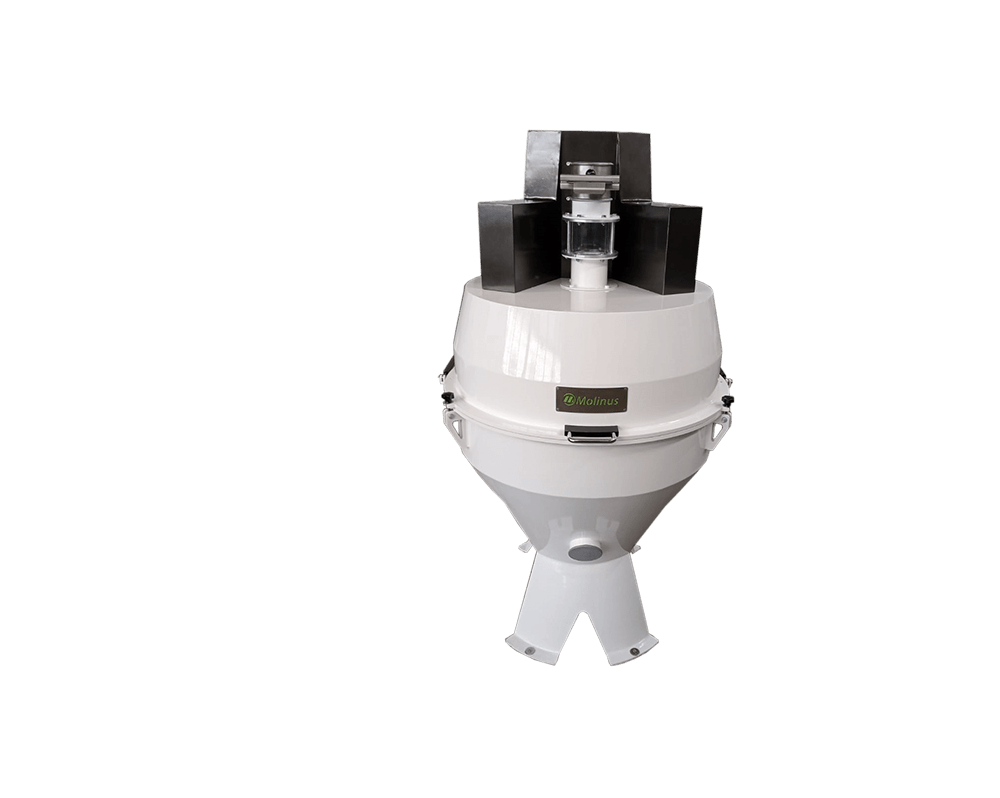

Hulling is an important process step in an oat processing plant. The Molinus MYSM impact huller is one of the main machines in this process and is used to hull for example oats, sunflower seeds, spelt as well as buckwheat and hemp.

Advantages of the impact huller:

It can be adapted to any system thanks to its plc-based nature.

It can be run as a separate process if desired.

Continuously adjustable speed range

Compact design

High hulling degree with low percentage of broken grains.

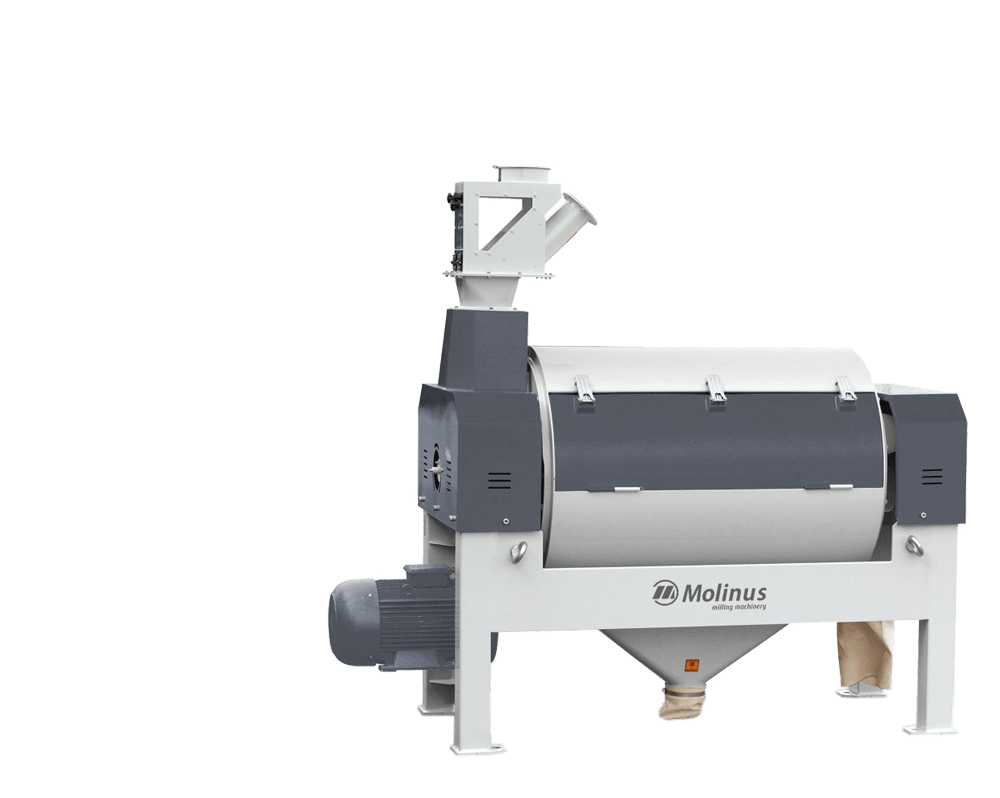

Molinus hammer mill is constructed as a single unit consisting of a base frame with mill housing, rotor for hammers, side doors with screen frames and direct coupled electric motor. With its robust structure and a construction that needs low maintenance, these machines offers high effciency. Balancing the rotor of mill has been done at the maximum working speed.

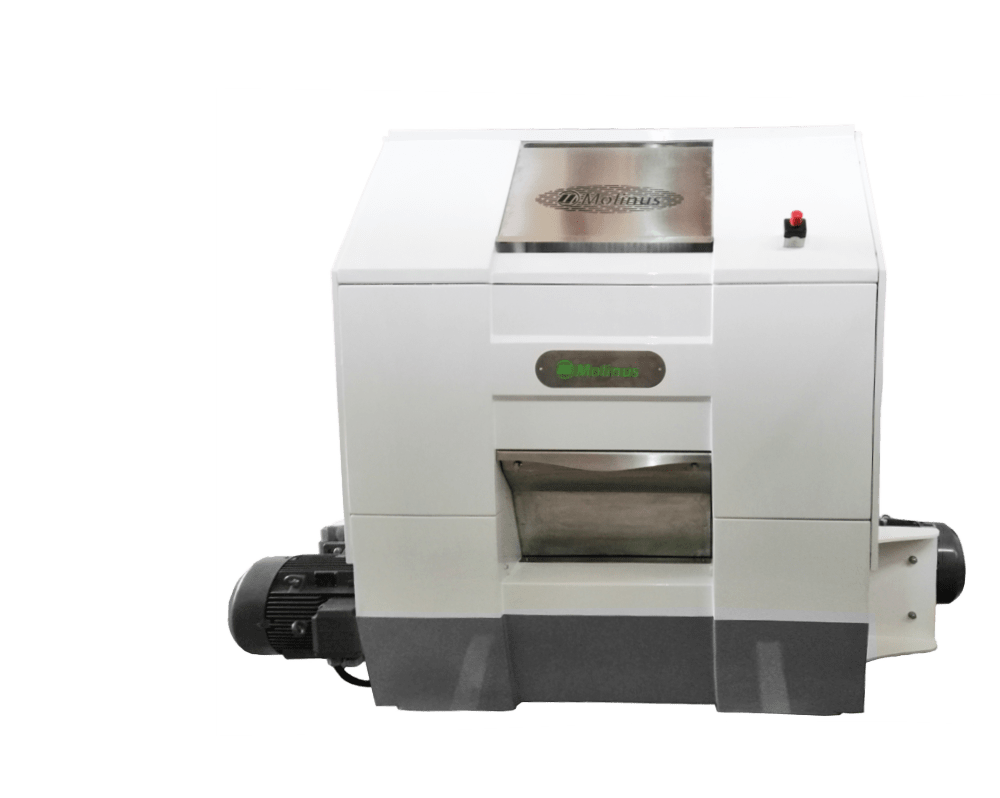

Flaking Mill MYEM allows to obtain healthy cereals by crushing grains such as oats, rye, wheat and barley.

It can be integrated into any system or controlled separately from other processes.

It sieves the sticky flour coming from filter and feeds to the system.

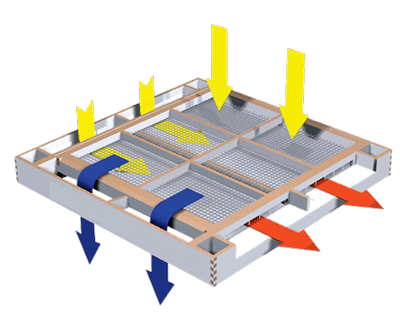

Pallets are mounted on chocks on a shaft which made up the rotor group. With eccentric weights the housing makes a vibratory motion. The position of the pallets and the eccentric weights can be adjusted.

- Used for sifting break and flour stocks and for sorting different grain types in flour, corn and semolina mills.

- Quiet and efficient sieve cleaning

- Excellent sanitation

- Easy access for cleaning

- Minimum maintenance and service necessity

- Centrifugal weight of the motor facilitates optimum throw of the sifter

SCOPE OF USE

Vibro Bran finishers are used in flour mills to seperate the flour stuck on the bran to refeed the system increasing the extraction and preventing the loss.

a) Can also be used as a bran finisher

b) The sieve does not choke up due to the vibration action of the machine

c) Perforation size of perforated screen is easily exchanged to suit the desired flow diagram

WORKING PRINCIPLE OF THE MACHINE

It is used in machine cleaning section. It is used for watering, washing and washing operations with water-operated, wheat or barley products. Same timw, also performs the stone separation process during washing. Machine size is selected according to the size of the machine.

USAGE PURPOSE

It is used for cleaning and classifying the semolina in the flour and semolina factories.

WORKING PRINCIPLE

A product with adjustable flow rate; thanks to a screen, it is spread neatly across entire sieve surface.

The sieve process is carried out with 2- or 3-fold sieve.

The production range is from 150 mm up to 820 mm in diameter and up to 2.200 mm in length.

It is used to separate air from the product, which is discharged from a cyclone separator into pneumatic systems. It is installed underneath the cyclone separators and air filters. It works with the negative pressure as well as an air seal against leakage.

The machine is used in carrying cereals and cleaning jet filter bags.

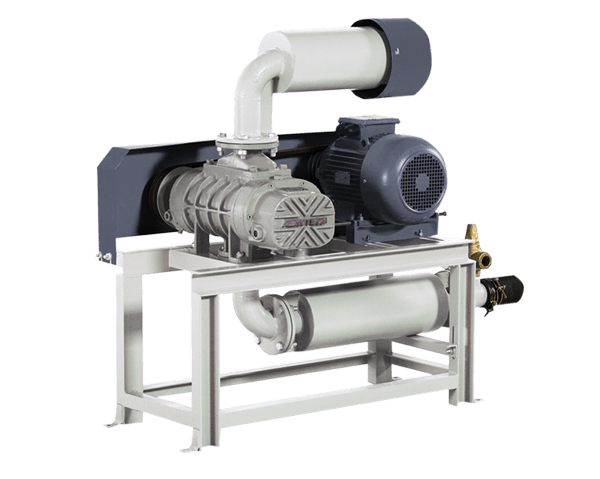

The blower is a low pressure pump with a high flow rate. In our applications, it is used to meet air requirements of the jet filter, and to transport cereals.

The blower is preferred according to the intensity and tonnage of the product to be carried, by calculating horizontal and vertical distances and even the number of right-angled elbows to be used.

Equipment And Spare Parts For Mills

Equipment for flour mills.

The widest selection of equipment and spare parts for flour mills. The Molinus product range includes the entire range of equipment for flour production plants, from large units such as roller machines or sieves, to individual units and parts for equipment.

From rubber products for conveyors to high-precision laboratory equipment that allows you to determine the quality of flour.