Centrifugal Casting in the Production of Drinding Rollers.

The main task of millers around the world is to get good quality flour. To achieve this, high quality, durable rollers are needed, as they are considered the "heart" of the mill. In the flour milling industry, the quality of the grinding rollers is just as important as the quality of the processed grain, as well as the quality and cost of the resulting flour. How can the quality of the rollers be assessed? What research is required for this? What are the most important quality indicators? The answers to these questions are simple. To do this, you should carefully trace the entire chain of their production, starting from the used raw materials to the resulting products at foundries.

Casting technology

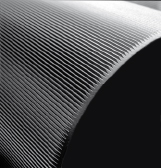

Previously, foundries used static casting (sand mold of standard casting) in the production of rolls. Currently, modern enterprises use new technologies of two-layer coating by the method of centrifugal casting. This achieves a homogeneous hardness throughout the roller thickness and a denser structure of the material from which it is made. The elements used in the casting of rolls are different for each manufacturer. The correct selection of these elements significantly affects the quality of the rollers. The grain has a rough surface and can therefore abrade hard materials such as glass and ceramics. If a material of low hardness is used for the manufacture of rollers, this will facilitate their manufacture, but will create big problems, in particular, additional costs for cutting and operating such rollers. This problem can be solved by using the know-how of the chemical composition and composition of the casting of the manufacturing plants. In the production of rollers for torn systems, the main thing is the maximum hardness of the starting material and the uniformity of cutting of the grooves, and for grinding systems - the average homogeneous hardness and uniform micro-roughness. Rollers manufactured in factories with these features in mind will last a long time.

Bearing seats

Bearing seats must be made of high quality steel grades SAE-1040 or SAE-1050. Cast bearing seats are not durable. There is always a risk of bearing failure. It is not profitably for production, as it leads to downtime and unnecessary expenses for repairs and maintenance.

Roller processing

Advantages of two-layer casting. The use of inductive melting, spectral analysis methods, alloying elements and CNC-controlled equipment has made it possible to create high-quality double-coated rolls by centrifugal casting.

Qualified specialists use high-quality technological equipment to check the rollers for centrifugal runout, for the uniformity of the microroughness of the surface of the smooth rollers and the correctness of cutting the grooves of the grooved rollers.

Rollers with a two-layer coating, obtained by the method of centrifugal casting, have a number of advantages:

- uniform hardness throughout the thickness and the entire depth

- ;

- denser material structure;

- durability;

- high work efficiency;

- versatility.

These rolls can be installed on roll mills of various manufacturing plants. They are successfully used in many flour mills in Russia and the CIS countries, and are also exported to more than 40 countries around the world, including the USA, Germany, Italy, France, Belgium and North Africa. The products have been awarded the European quality certificate ISO 9002.

The use of inductive melting, spectral analysis methods, alloying elements, CNC-controlled equipment, made it possible to create high-quality rollers with a double-layer coating by the method of centrifugal casting. Centrifugal runout, microroughness of surfaces, grooving are applied and checked by highly qualified specialists using high-quality technological equipment according to the customer's needs.

The main principle of the company: "Customer satisfaction" is achieved through careful control at every stage of the technological process (from the supply of raw materials to finished products). Finished products are delivered to the customer after a thorough check of technical indicators for compliance with the required quality.

Service, constant communication with the customer allows us to make a decision in time and solve the problem.

Our grinding rollers are successfully used by many flour mills in Russia and the CIS. They are installed on roller mills from different manufacturers. You can familiarize yourself with other spare parts and components for flour mills in the section of the catalog "Mills groats factories"